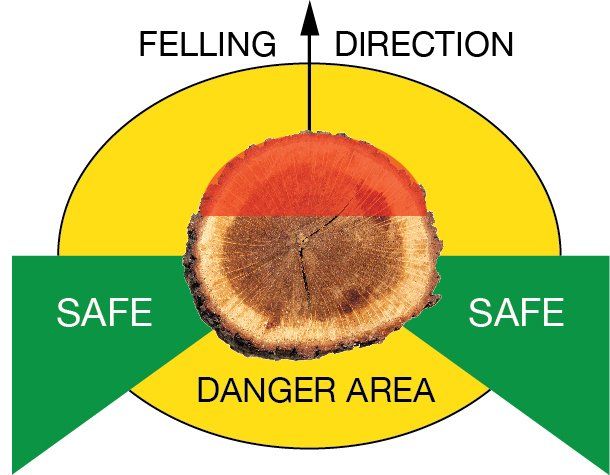

#1 – Identify height and hazards – Decide on the most desirable direction to fell the tree. Use a reliable method to determine the height of the tree relative to the direction of the fall. Look for tree defects, decay, electrical conductors, or any other characteristics of the tree that may affect the felling plan. Consider obstacles within the tree felling site such as structures, pavement, and outdoor furnishings. While some can be moved if necessary; others will have to be avoided. Assess the strength and direction of the wind.

#2 – Assess the side lean – This often determines whether or not the hinge will hold and whether or not you may need to remove some weight from the “bad” side. This also provides the information necessary to determine the “good” and “bad” sides of the tree for the feller to stand when making the final cut.